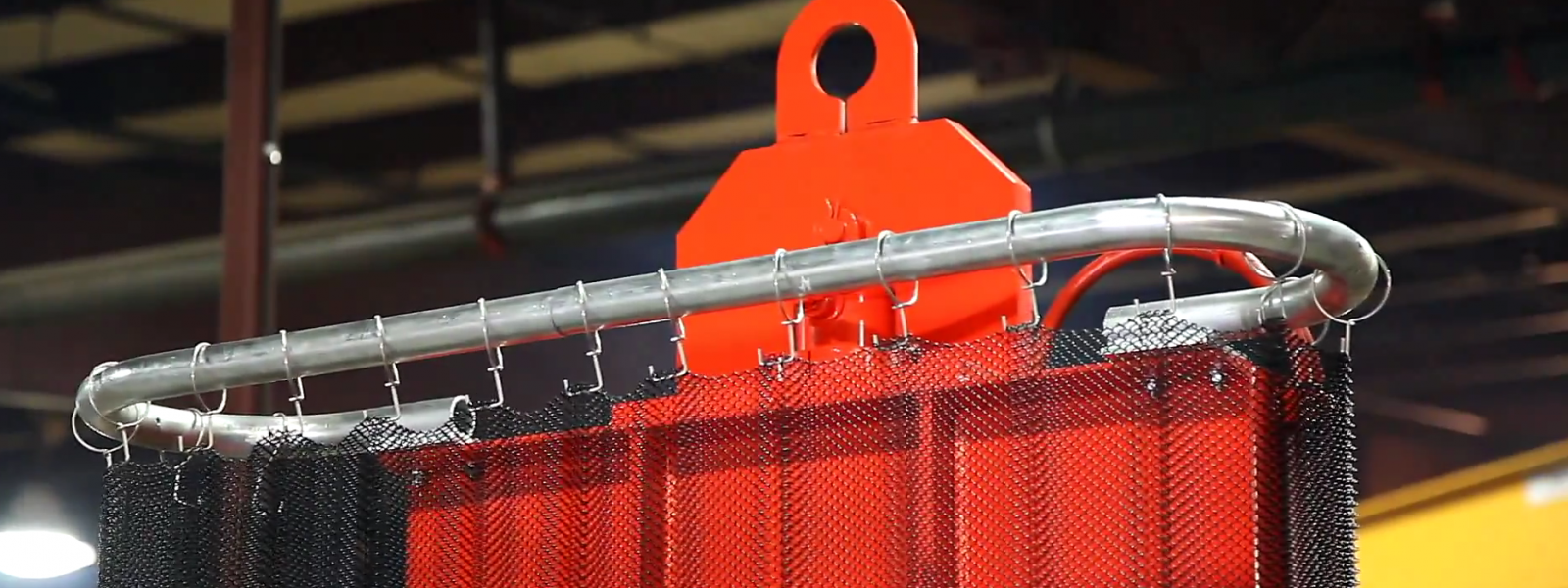

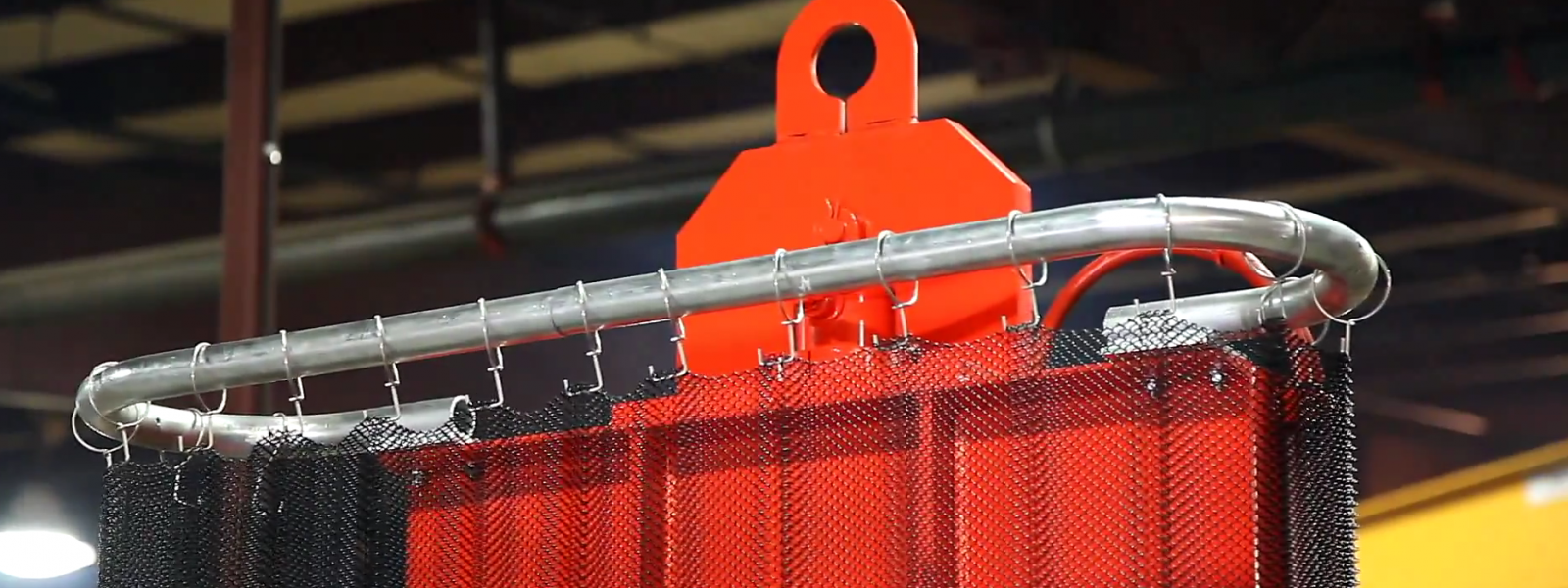

Cascade Industrial Safety and Security Systems can be manufactured to specific dimensions to meet various applications and requirements – offered in an assortment of weave sizes, materials, colors, and attachment systems. The flow-through design of GuardianCoil allows light into the work area, ventilation, and gives operators a view of operating machinery.